Raw Materials

The primary material for plastic windows is polyvinyl chloride (PVC). To create strong and durable windows, various additives are used, such as stabilizers, plasticizers, and reinforcing components.

High-quality materials and strict control at every stage of production

Learn more

The primary material for plastic windows is polyvinyl chloride (PVC). To create strong and durable windows, various additives are used, such as stabilizers, plasticizers, and reinforcing components.

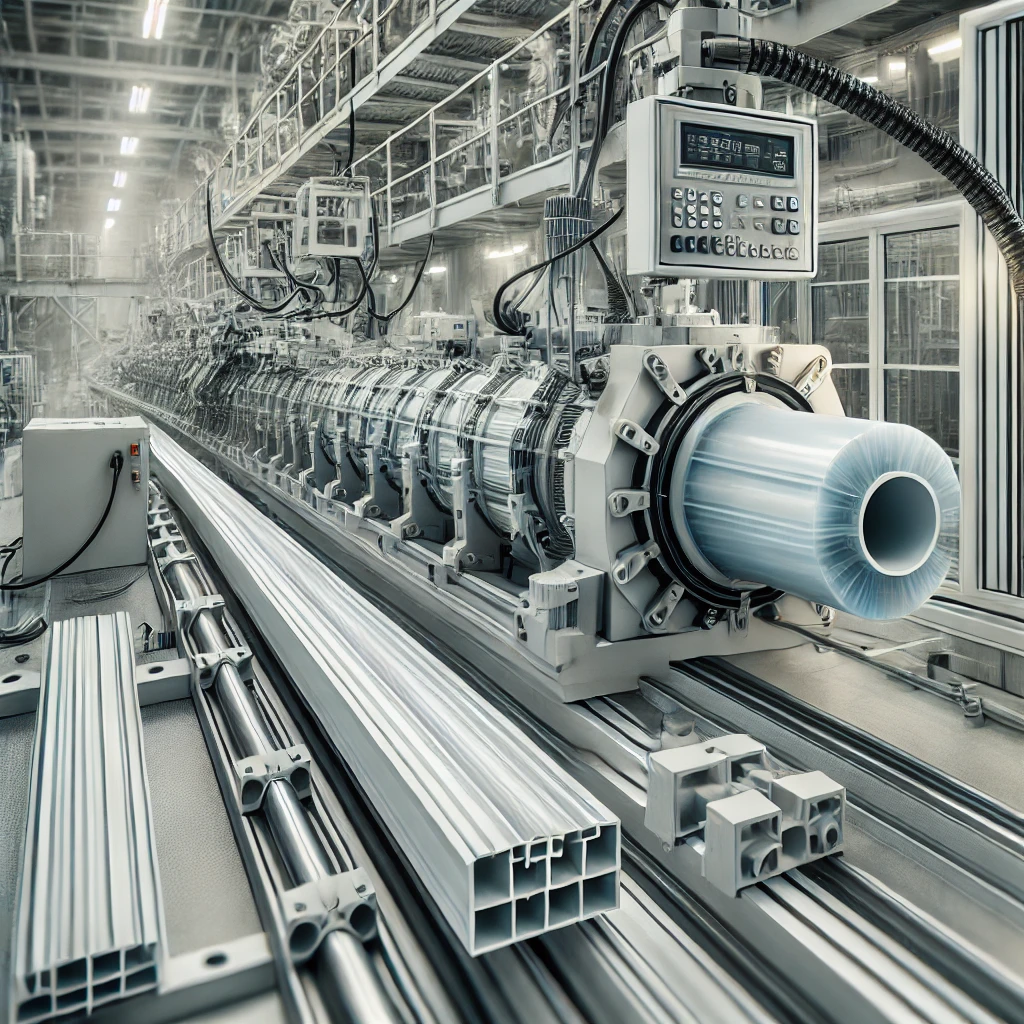

The PVC compound is heated and pushed through an extruder to form window profiles. The profile is then cooled and retains its shape.

To increase the strength, the plastic profile is reinforced with metal elements, giving the structure rigidity and resistance to deformation.

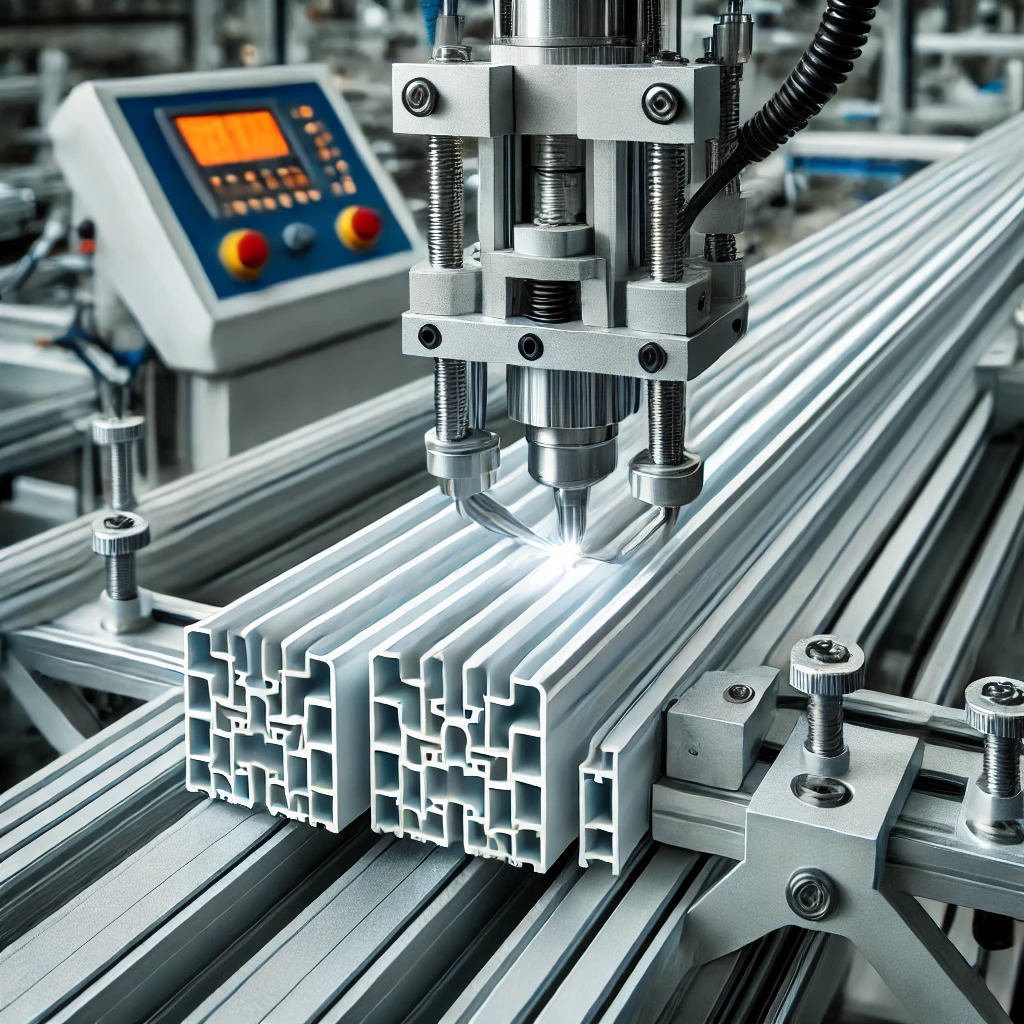

The profiles are cut to the desired length and then welded to form frames and sashes. Welded joints are cleaned to ensure a neat appearance.

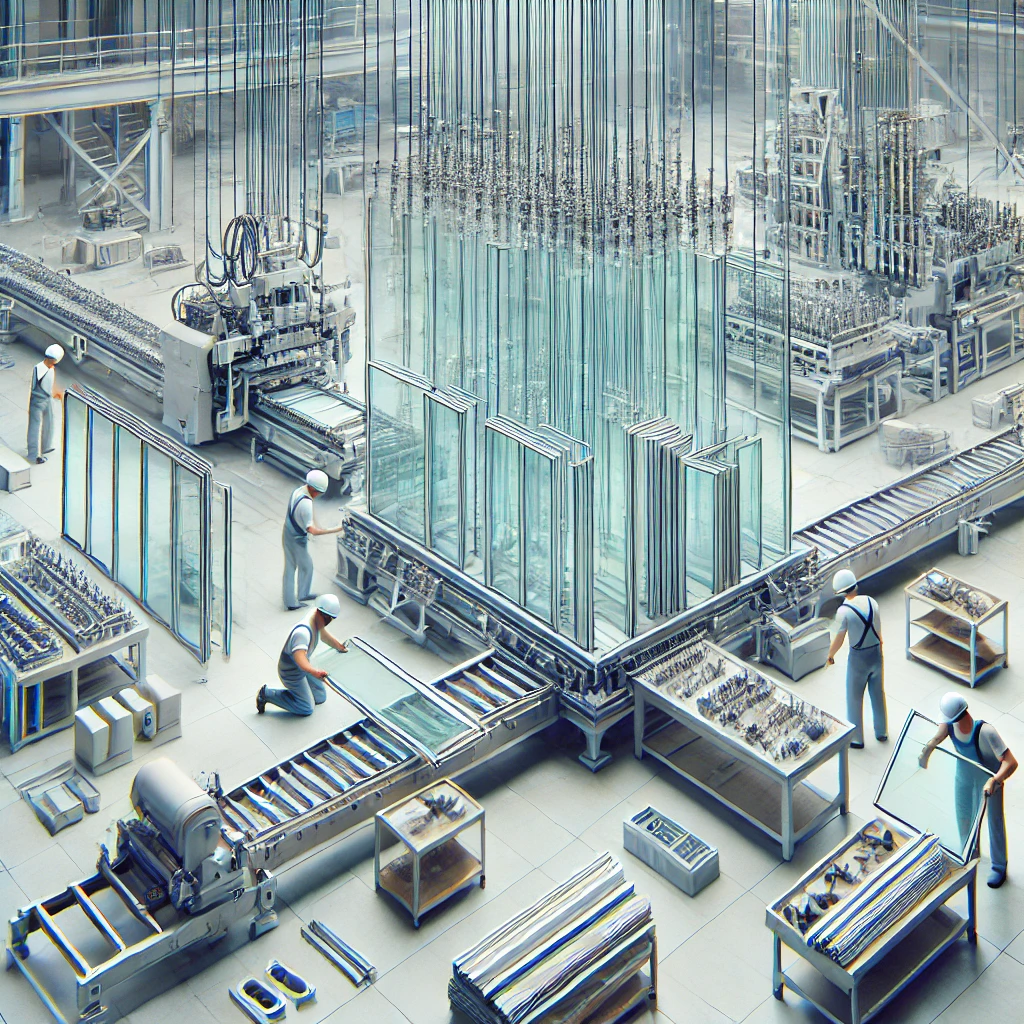

Glass units are composed of several layers of glass, hermetically sealed together with spacers and sealant.

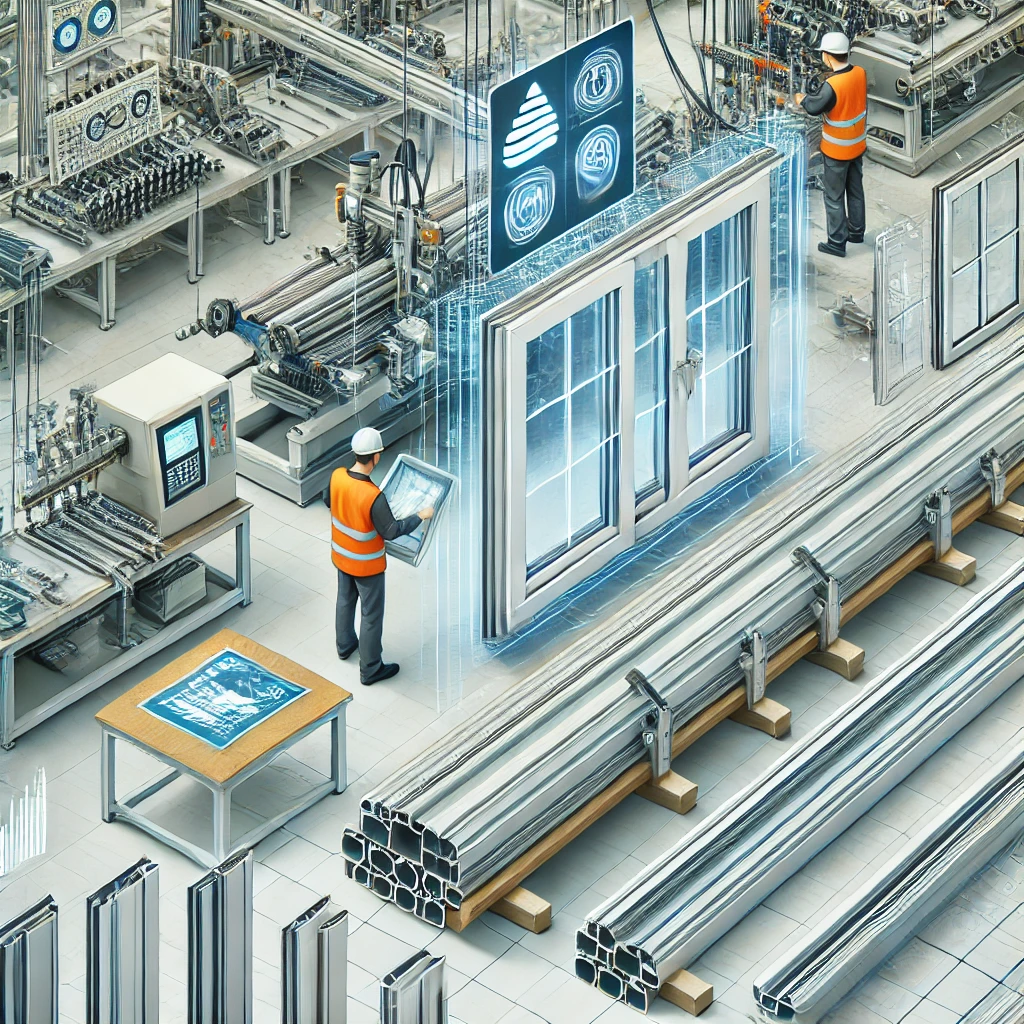

At each stage of production, strict quality control is carried out. Both raw materials and finished products are tested to ensure compliance with industry standards.

Production lines can produce from 100 to 1000 windows per shift, depending on the capacity of the enterprise and the technologies used. All products comply with GOST, EN, and energy efficiency standards.